Groupe Beneteau opts for Elium® recyclable resin for its largest yacht

The use of Elium® resin, which was developed by Arkema in collaboration with the Group's business/innovation teams, is a major project involving a large number of internal and external teams. This innovation is fully in line with Groupe Beneteau's global strategy, and more specifically with its

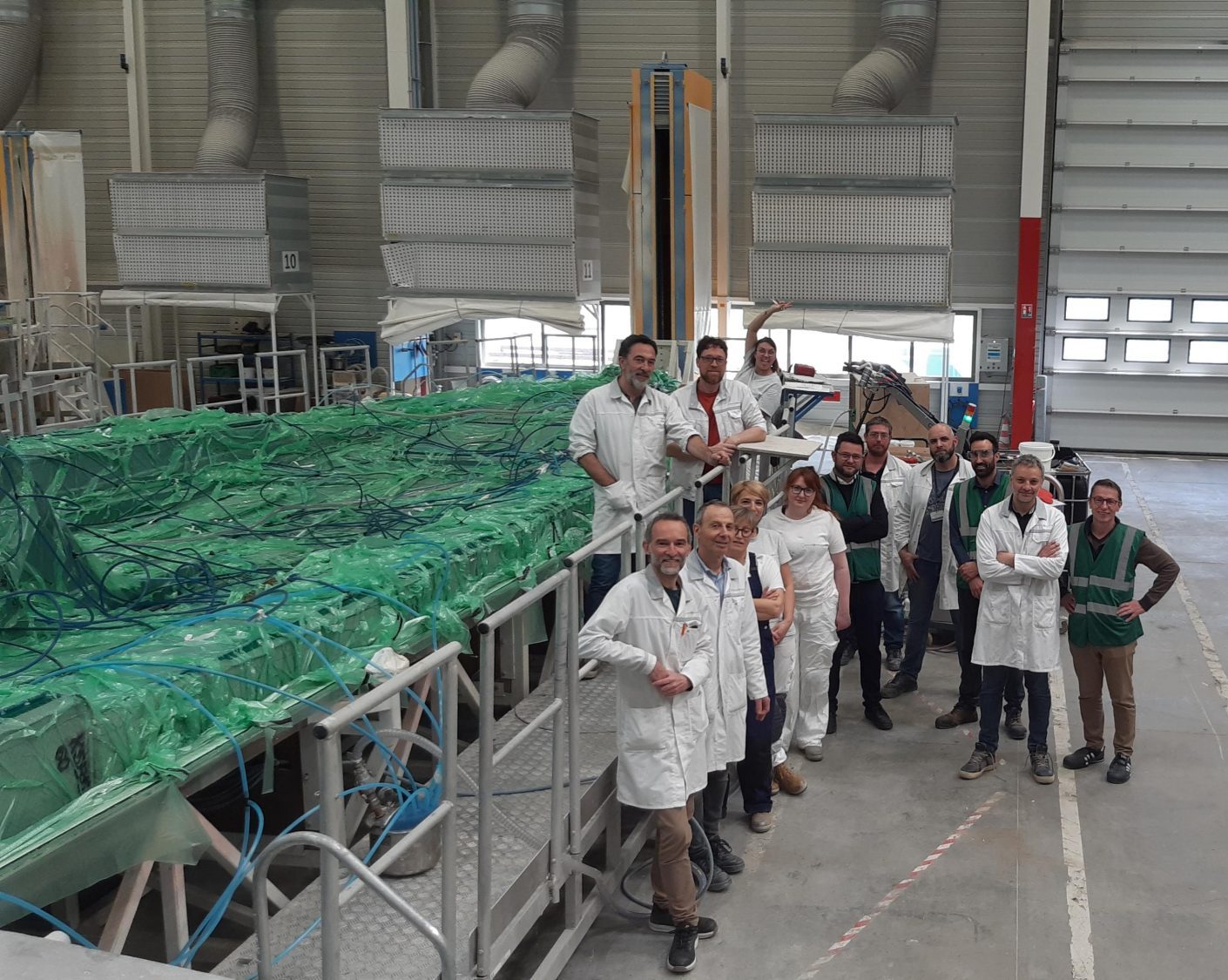

"B-Sustainable" programme. In 2024, a major breakthrough was unveiled with the use of this resin in the manufacture of a 60-foot sailing yacht, the Group's largest boat: the Oceanis Yacht 60.

“The project has been four years in the preparing," says Christophe PÉTIGNY, innovation and sustainable development project manager at Groupe Beneteau. We're moving forward in stages: we started with a prototype and then moved on to a series of small boats for regattas. The question of the Group’s standard production boats soon arose. We chose to target an initial boat built industrially in Saint-Gilles-Croix-de-Vie, quite a large yacht, which is not manufactured in too large a volume to be able to implement the process on a few boats before rolling out more widely, and on which we can afford a little extra cost: this equation led us to the Oceanis Yacht 60.“

Change of scale

The industrial stage changes the game: “We're talking about a workshop with its own industrial constraints, which runs on a cadence with teams accustomed to using a historic resin,” stresses Christophe. The challenge is to get the teams involved in the project, to get them to develop their skills with a material that is less permissive than polyester from the outset." Despite the difficulties encountered, this technical challenge on an industrial scale makes sense for Groupe Beneteau, particularly in environmental terms. As composite is one of the industry's major challenges in terms of recyclability, the Group is working on this subject to make progress and innovate in terms of environmental performance.

Adapting to all levels

Behind Elium®: Arkema has been working on this resin for just over ten years. "Our starting point was to say that to make composites recyclable, we had to completely rethink their chemistry and redesign the resin that goes into them," explains Guillaume CLEDAT, head of Elium® activities at Arkema. "Elium® was born on this principle. It is a thermoplastic and acrylic resin that produces a composite that can be compounded (for moulding) and depolymerised*. "We need a resin that is ISO-compliant in terms of mechanical strength, resistance to the elements, marine testing... and that can be adapted to our infusion processes," insists Christophe. This is one of the biggest challenges of the partnership, as the Arkema and Groupe Beneteau teams work together openly to perfectly adapt the parameters for applying the resin.

All players united around a single objective

The strength of the concept lies in the fact that the Beneteau Group, in partnership with Arkema, has brought together all the players needed to industrialize the recycling of Elium® resin: Veolia for the collection of production waste; Owens Corning and Chomarat for the glass fiber sector (companies that reuse glass fiber after recycling) and Composite Recycling, a Swiss start-up, which has designed a solution for recovering glass fibers and resin, creating a post-treatment process for reintroducing them into the manufacture of new fibers.

Since the introduction of Elium® resin:

almost 35 Boats manufactured with Elium® resin

Of which in 2024

• 1 BENETEAU First 44,

• 2 BENETEAU Oceanis Yacht 60

• 30 JEANNEAU Sunfast 30

A major step forward for Groupe Beneteau and the marine sector.

Christophe PÉTIGNY, Innovation and Sustainable Development Project Manager at Groupe Beneteau, and Guillaume CLEDAT, Elium® Business Manager at Arkema, tell us more.

Tell us about your collaboration...

Christophe PETIGNY: We are codeveloping this specific resin. The base resin was proposed by Arkema and we are developing it as we go along with our tests. It's all hands on deck: technical teams on both sides, laboratories on both sides, purchasing, production, industrialisation and supply. It's vital that we move forward together!

Guillaume CLEDAT : Partnership is essential. Our teams work together closely, monitoring developments and progress on both sides. That's how we've managed to achieve such a transformation. We also have the capacity to mobilise the entire recycling value chain, and this is one of the prerequisites for the success of our project. Groupe Beneteau is the leader in its market and maintains this position by being a pioneer in technology. Working with teams with this level of commitment is a real opportunity!

What are the particular challenges involved in using this resin in mass production?

CP: These are the same controls and the same procedures as for polyester. However, the parameters are much more delicate and sensitive. Elium® resin demands even greater rigour, care and attention. It's an opportunity for our teams to become increasingly expert and to develop their skills. What we need to do now is find the right compromise so that it's not too complicated to manage. Meeting this technical and environmental challenge is one of our objectives: it's part of the future of boating that's at stake!

GC: I agree with Christophe. For this reason, we are working together on a formulation optimisation project. The challenge is to make Elium® resin more robust, so that it can be used on more and more boats without systematically requiring overly specialised skills.